In view of the special performance requirements of special yarns, what unique optimization measures does the special yarn spinning equipment have in terms of process?

The special properties of special yarns usually include but are not limited to high strength, high modulus, high temperature resistance, wear resistance, antistatic, antibacterial and mildew resistance, good dyeability, etc. The realization of these properties has extremely high requirements for temperature control, drawing speed, fiber cross-sectional shape, surface treatment, etc. in the spinning process.

In the spinning process of special yarns, temperature is one of the key factors affecting fiber structure and performance. The temperature calibration equipment of the Barmag hot drawing machine can ensure that the temperature at each stage of the spinning process is accurately controlled within the set range to avoid the influence of temperature fluctuations on fiber properties. This high-precision temperature control is essential for the production of special yarns with specific thermal stability.

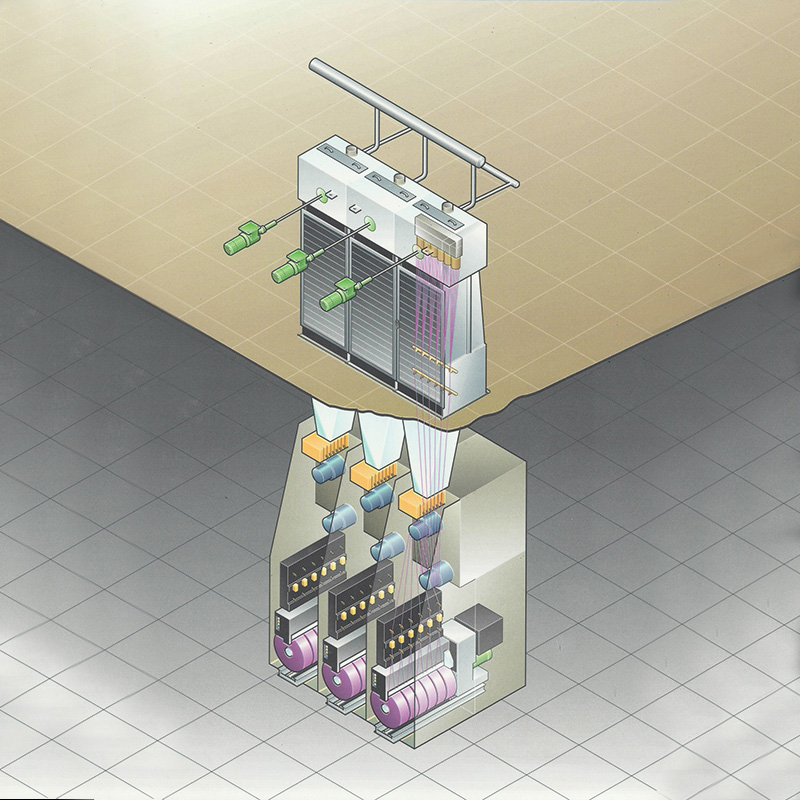

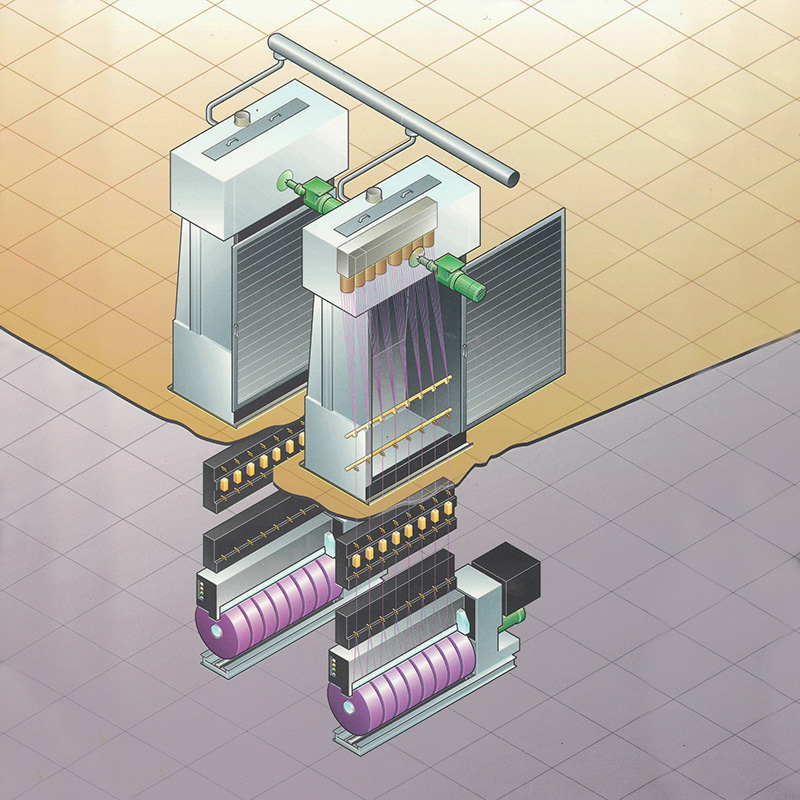

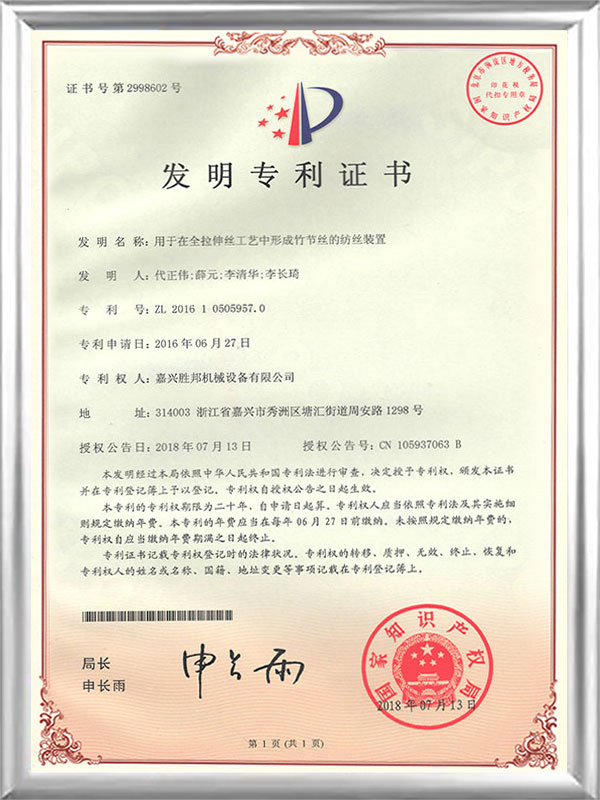

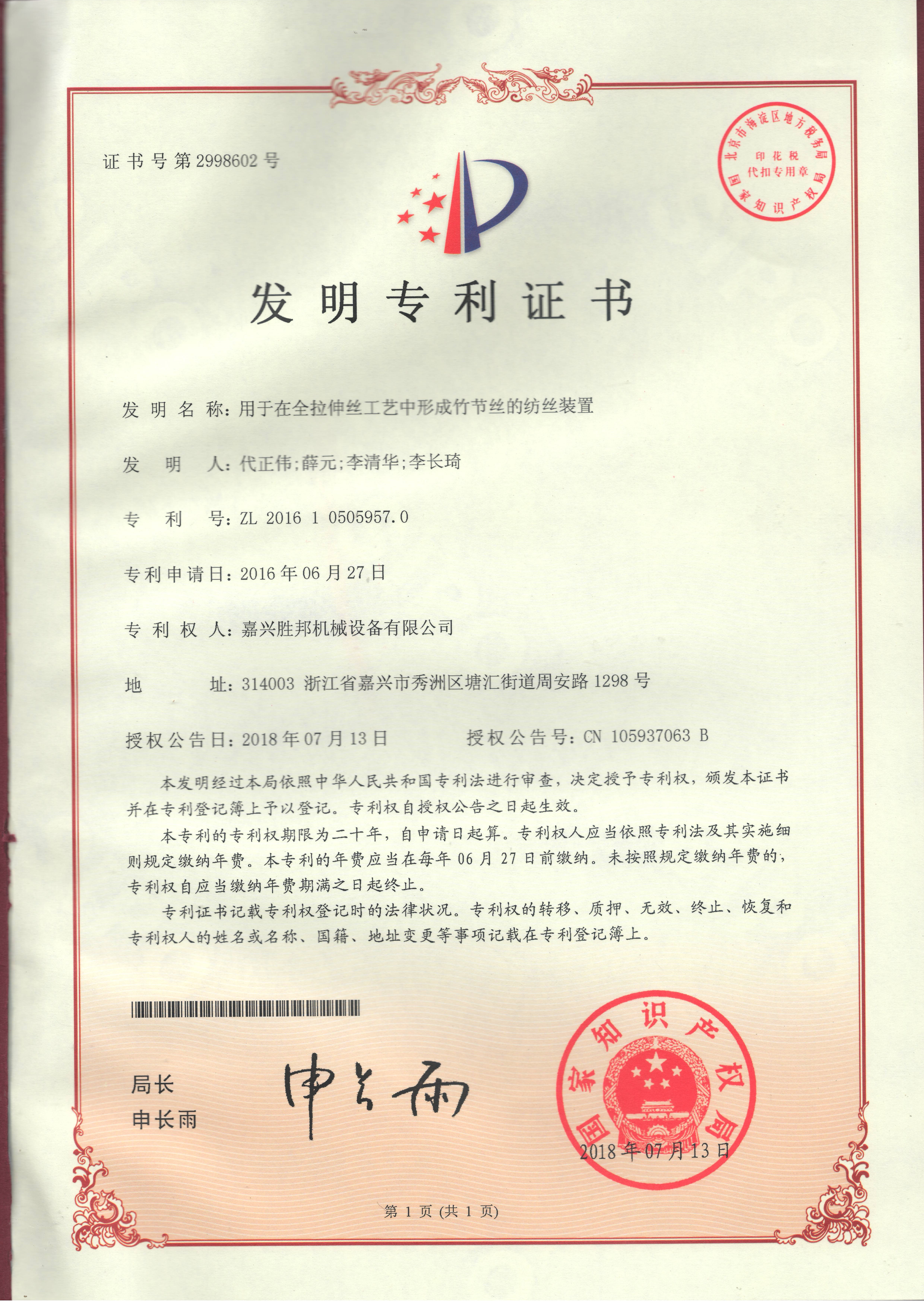

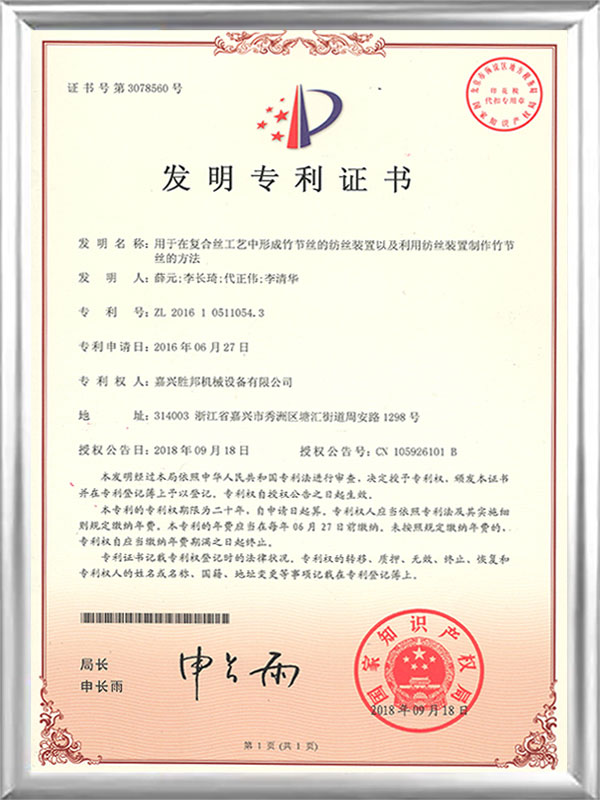

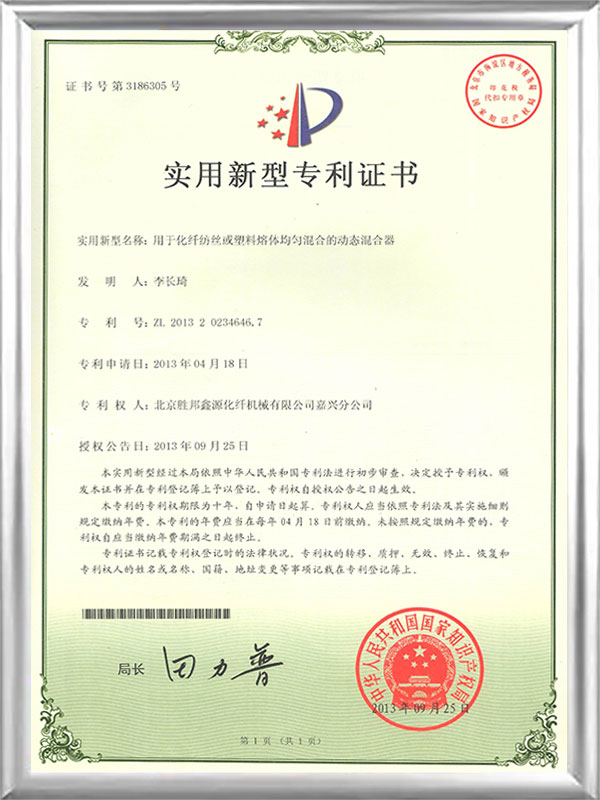

The cross-sectional shape of the fiber directly affects its gloss, hygroscopicity, warmth retention and other properties. In order to meet the special needs of special yarns, spinning equipment needs to have the ability to adjust the cross-sectional shape of the fiber. Through advanced CNC machine tools and precise mold design, Jiaxing Shengbang Mechanical Equipment Co., Ltd.. is able to produce fibers with special cross-sections, such as hollow, trilobal, flat, etc., thus giving the yarn unique physical and chemical properties.

The production of special yarns often requires the fiber surface to have specific microstructures or chemical properties. The use of high-energy ion beam technology is a non-contact, pollution-free surface treatment method. By bombarding the fiber surface with high-energy ion beams, its micromorphology can be changed, the surface roughness can be increased, or specific chemical functional groups can be introduced, thereby enhancing the adhesion, wettability or reactivity of the fiber. Especially for the spinnerets of chemical fiber plants, after a period of use, there will be phenomena such as increased tension and increased tension differences between tows. The high-energy ion beam technology used by the company can effectively change the surface structure of the nozzle, so that the imported nozzle can be restored to its original state after 4-5 years of use, ensuring the stability of the spinning process and the uniformity of the yarn quality.

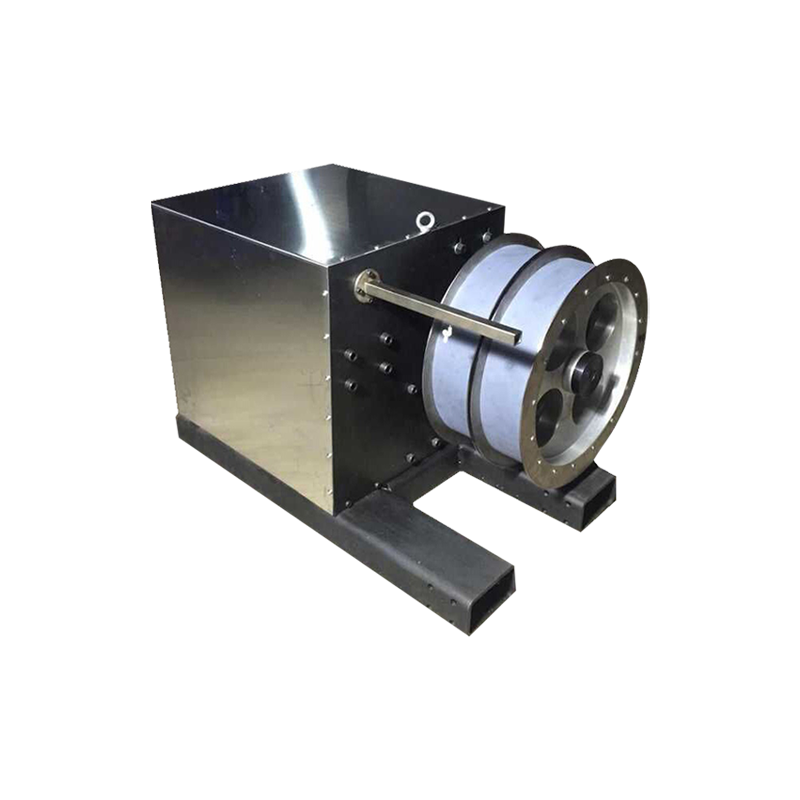

Stretching and heat setting are key steps in the spinning process that determine the final performance of the fiber. Special yarn spinning equipment is equipped with high-precision stretching devices and heat setting equipment, which can accurately control the stretching ratio and heat setting temperature to ensure that the fiber obtains the required strength, modulus and dimensional stability. Especially for special yarns that require high strength and high modulus, such as carbon fiber precursor yarns used in the aerospace field, accurate stretching and heat setting processes are essential.

The production of special yarns has extremely high requirements for quality control. Special yarn spinning equipment has advanced online monitoring equipment, such as precision measuring instruments and automated detection systems, which can monitor key indicators such as fiber diameter, strength, elongation, etc. in real time to ensure the consistency and stability of product quality. This combination of online monitoring and quality control systems has greatly improved production efficiency and product qualification rate.

With the development of intelligent manufacturing technology, the intelligence level of special yarn spinning equipment is also constantly improving. By introducing automated machinery and intelligent management systems, the production process has been digitized, networked and intelligentized. This not only improves production efficiency and flexibility, but also makes data collection, analysis and application in the production process possible, providing strong support for further optimization of spinning processes and product quality.

In the production process of special yarns, the performance of special yarn spinning equipment directly affects the quality of the fiber. Jiaxing Shengbang Mechanical Equipment Co., Ltd. introduced plasma spraying equipment from AVIC Manufacturing Technology Research Institute to strengthen the surface of key components of spinning equipment. Plasma spraying technology can form a dense, uniform and strong bonding coating on the surface of the equipment, improve the wear resistance, corrosion resistance and heat resistance of the equipment, thereby extending the service life of the equipment and ensuring the stability of the spinning process and the quality of the yarn.

简体中文

简体中文